Product Detail

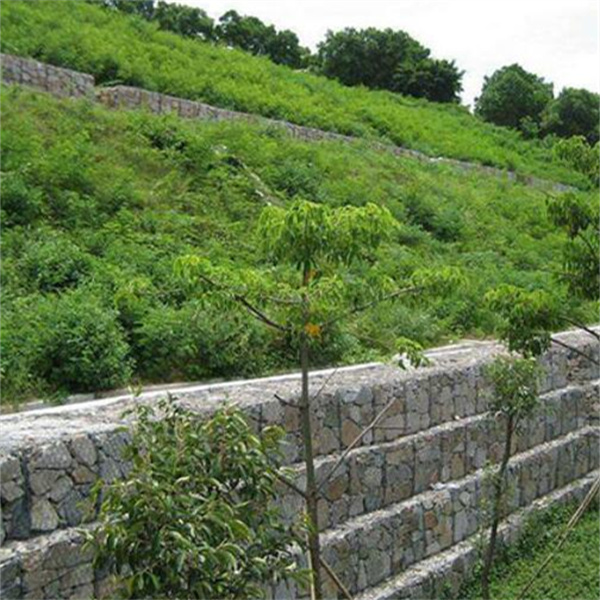

Gabion basketses are made of heavy galvanized wire / ZnAl (Golfan) coated wire / PVC coated wires, the mesh shape is hexagonal style. The gabion basketses are used widely in slope protection, foundation pit suporting, mountain rock holding, river and dams scour protection.

gabion basketses can be supplied in various lengths, widths and heights. In order to strengthen the boxes,all the edges of the structure shall be selvedged with wire of bigger diameter.

Wire Materials:

1) Galvanized Wire:about zinc coated,we can provide 50g-500g/㎡ to meet different country standard.

2) Galfan Wire:about Galfan,5% Al or 10%Al is available.

3) PVC Coated Wire:silver,black green etc.

|

Gabion bakset common specification |

|||

|

gabion baskets (mesh size): 80*100mm 100*120mm |

Mesh wire Dia. |

2.7mm |

zinc coating:60g,245g, ≥270g/m2 |

|

Edge wire Dia. |

3.4mm |

zinc coating:60g,245g, ≥270g/m2 |

|

|

Tie wire Dia. |

2.2mm |

zinc coating:60g,≥220g/m2 |

|

|

Gabion mattress(mesh size): 60*80mm |

Mesh wire Dia. |

2.2mm |

zinc coating:60g, ≥220g/m2 |

|

Edge wire Dia. |

2.7mm |

zinc coating:60g,245g, ≥270g/m2 |

|

|

Tie wire Dia. |

2.2mm |

zinc coating:60g, ≥220g/m2 |

|

|

special sizes Gabion are available

|

Mesh wire Dia. |

2.0~4.0mm |

superior quality,competitive price and considerate service |

|

Edge wire Dia. |

2.7~4.0mm |

||

|

Tie wire Dia. |

2.0~2.2mm |

||

Application

Retaining wall structures;Prevention of current scour and erosion control;Bridge protection;Hydraulic structures, dams and culverts; Embankment protection; Rockfall prevention and soil erosion protection.

Features

(1) It is convenient to use, and can be used only by tiling the net surface into wall surfaces and building cement;

(2) the construction is simple and does not need special technology;

(3) Strong ability to resist natural damage, corrosion and adverse weather effects;

(4) can withstand large-scale deformation without collapsing. It plays a role in fixing heat preservation and heat insulation.

(5) The excellent technological foundation ensures the uniformity of coating thickness and has stronger corrosion resistance;

(6) Save transportation costs. It can be shrunk into small rolls and wrapped in moisture-proof paper, occupying little space.

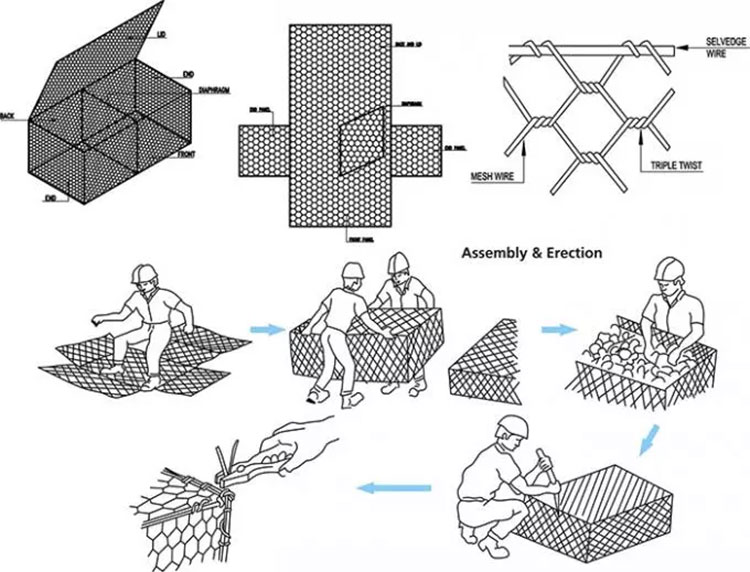

Installation Process

1. Ends,diaphragms,front and back panels are placed upright on the bottom section of wire mesh

2. Secure panels by screwing sprial binders through the mesh openings in adjacent panels

3. Stiffeners shall be placed across the corners, at 300mm from the corner. Providing a diagonal bracing,and crimped

4. Box gabion filled with graded stone by hand or with a shovel.

5. After filling,close the lid and secure with sprial binders at the diaphragms,ends,front and back.

6. When stacking tiers of the weled gabion,the lid of the lower tier may serve as base of the upper tier.Secure with sprial binders and add pre-formed stiffeners to exterior cells before filling with graded stones.

Strict Quality Control

1. Raw Material Inspection

Inspecting wire diameter, tensile strength, hardness and zinc coating and PVC coating, etc

2. Weaving Process quality control

For each gabion, we have strict QC system to inspect the mesh hole, mesh size and gabion size.

3. Weaving Process quality control

The most advanced machine 19 sets to make every gabion mesh Zero Defect.

4. Packing

Every gabion box is compact and weighted then packed into pallet for shipment,

Packing

The gabion box package is folded and in bundles or in rolls. We also can pack it according to customers special request